Converting

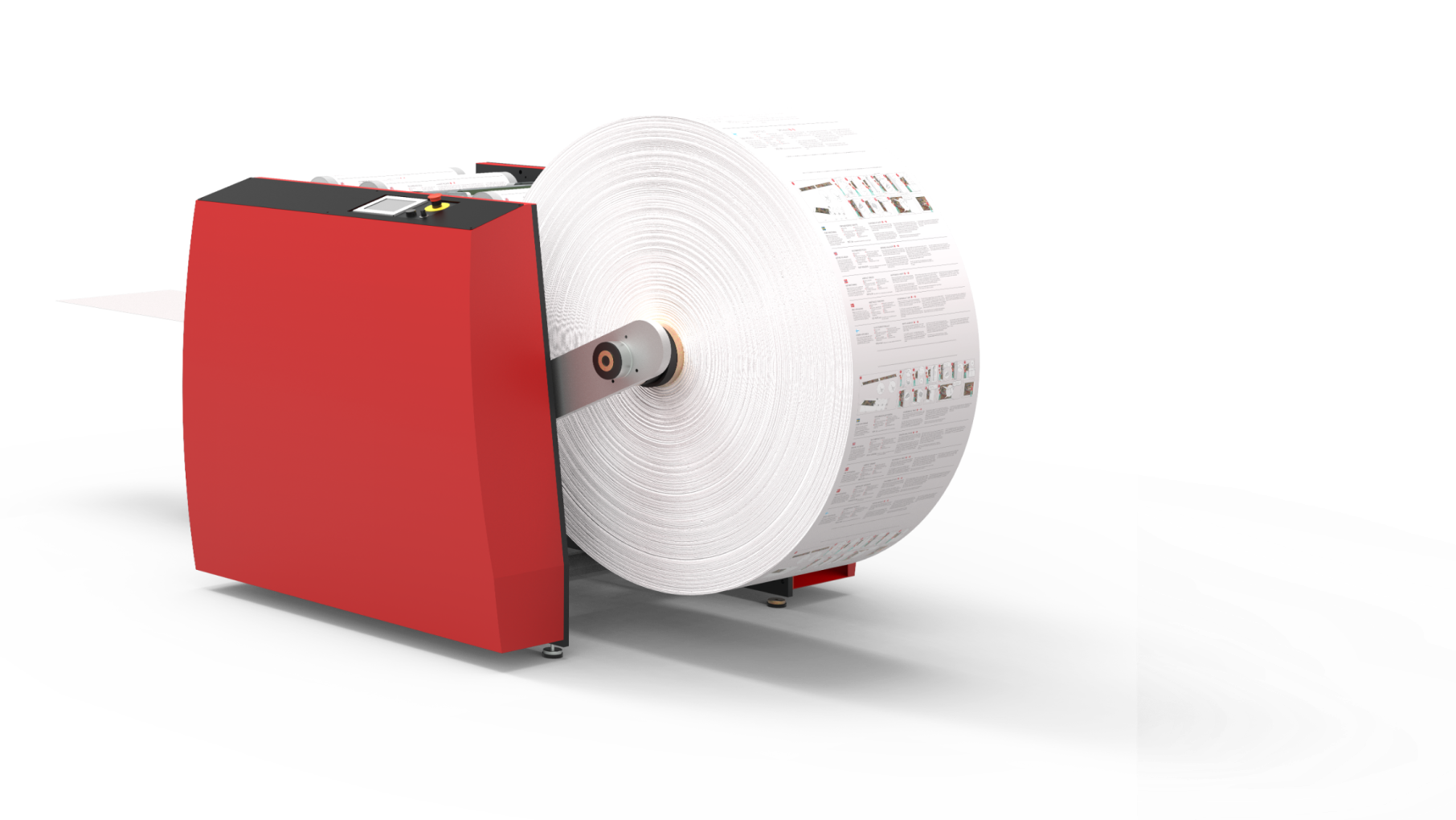

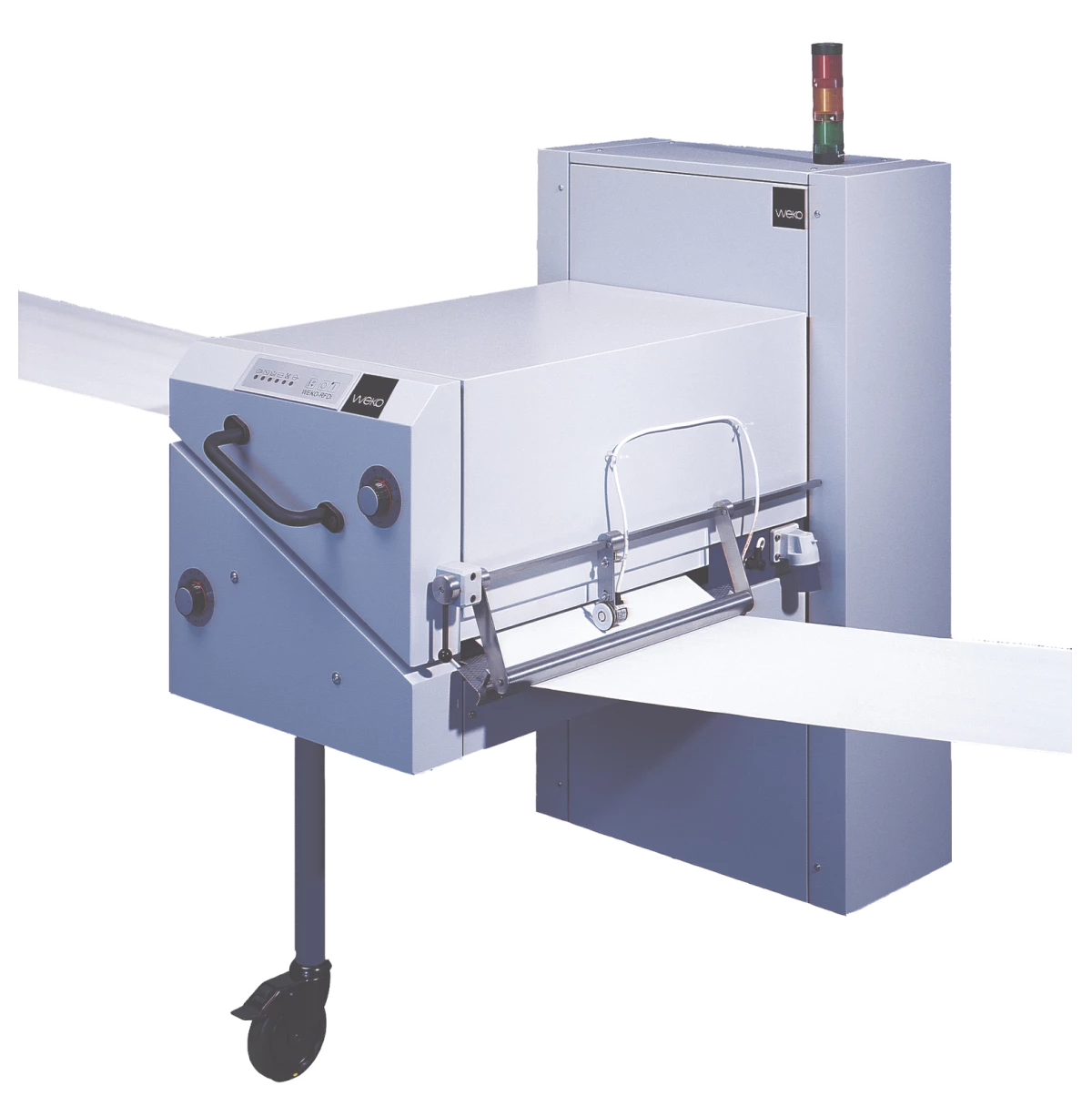

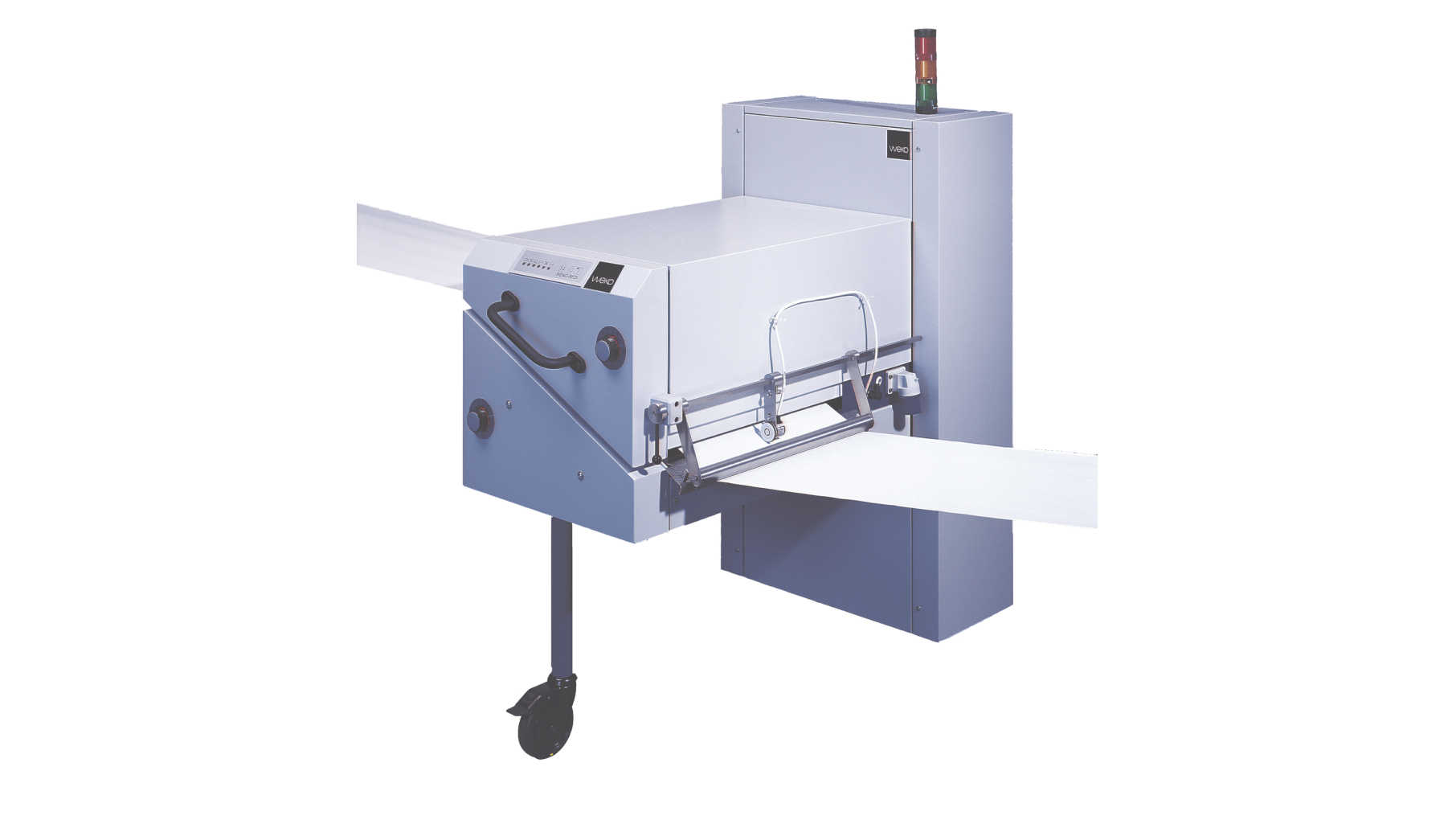

WEKO RFDi

Remoisturize the printed substrate to reduce the risk of waviness.

The electrophotographic printing process using a Xeikon machine requires heat, not only to fuse the toner unto the substrate but also to condition the material prior to printing. This heat will inevitably result in partial evaporation of the moisture present in the printed substrate. To reintroduce the vaporized moisture, the WEKO RFDi remoisturizer unit can be placed behind the press. The amount of moisture in the production environment differs from the moisture content in the printed material exiting the press. In order to reduce the risk of waviness, the printed substrate is moisturized immediately after printing using the WEKO RFDi unit. Print jobs will be more or less reactive to this, depending on the substrate, the structure of the media, the coating and the thickness.

Wanna see it in action?

Contact an expert Contact an expertSpecifications

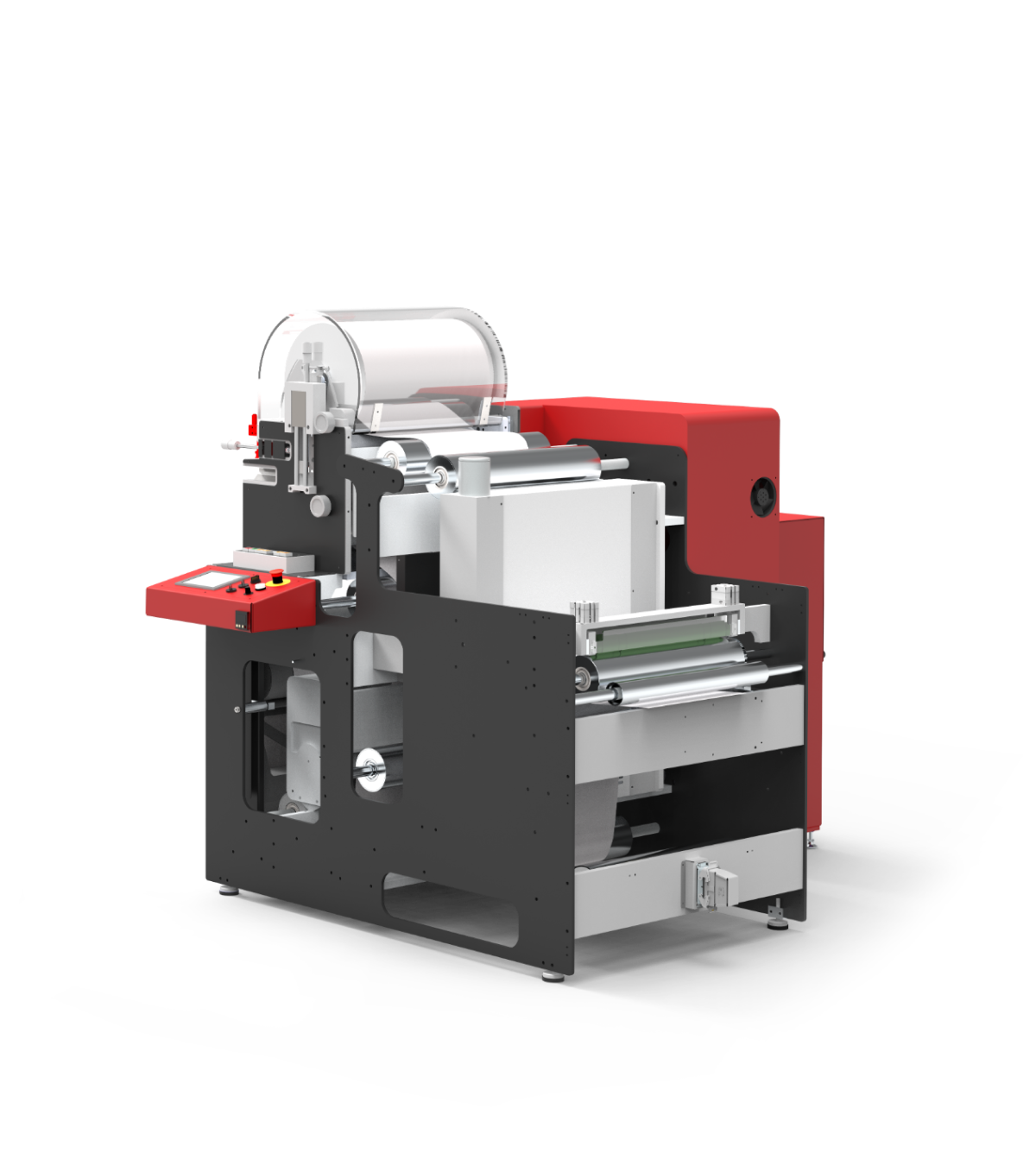

Supported web width

320-520mm (12.6""-20.3"")

Substrate support

Paper, paperboard… (substrate needs to be capable of absorption)

Wetting agent

To be diluted with water for improved absorption

Stand-alone unit

Automatically controlled by web movement

Dimensions (LxWxH)

674mm (25.5”) x 1274mm (50.15”) x 1240mm (48.8”) (min. WEKO RFDi unit only, typically an extra tunnel is required)

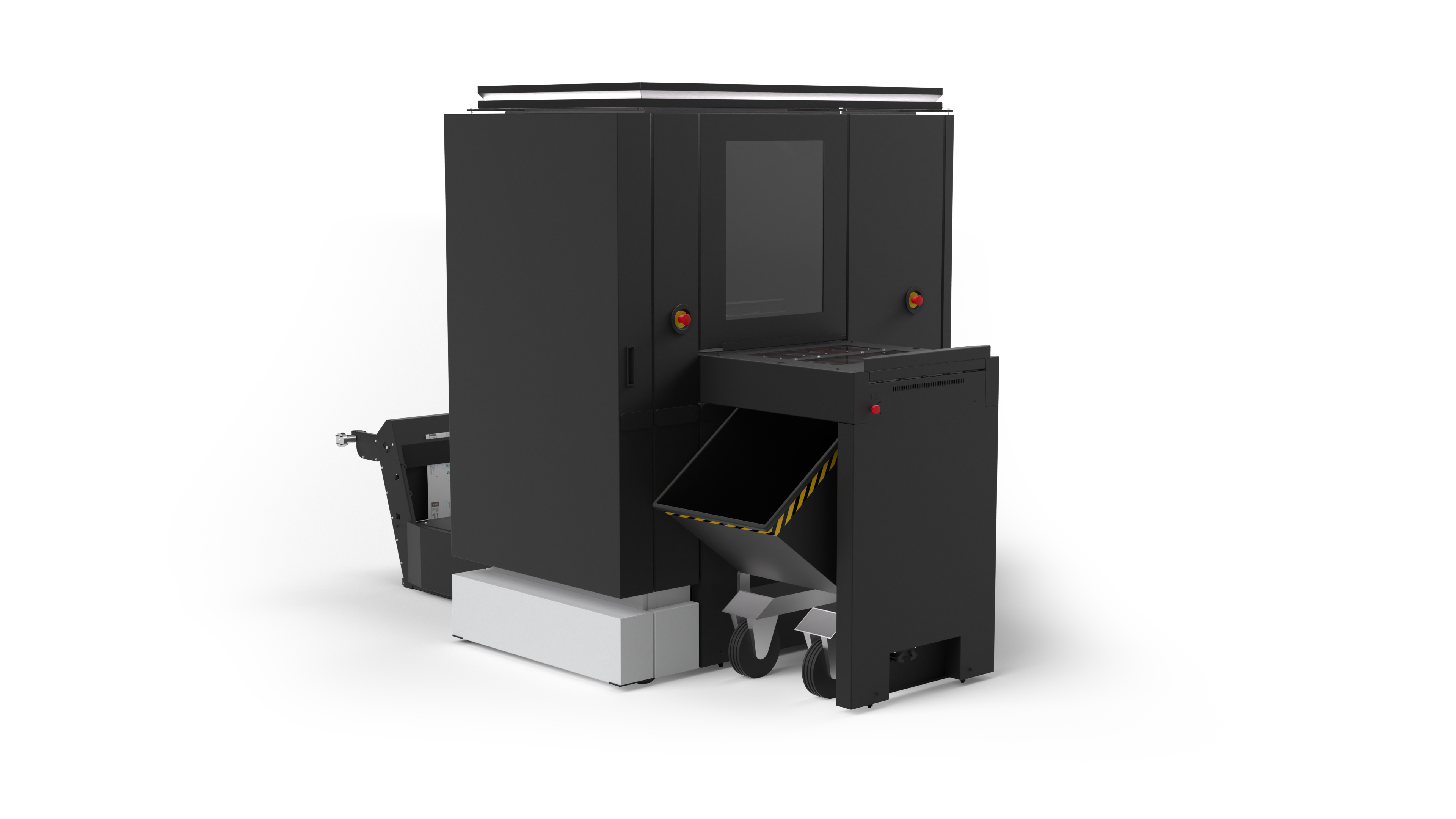

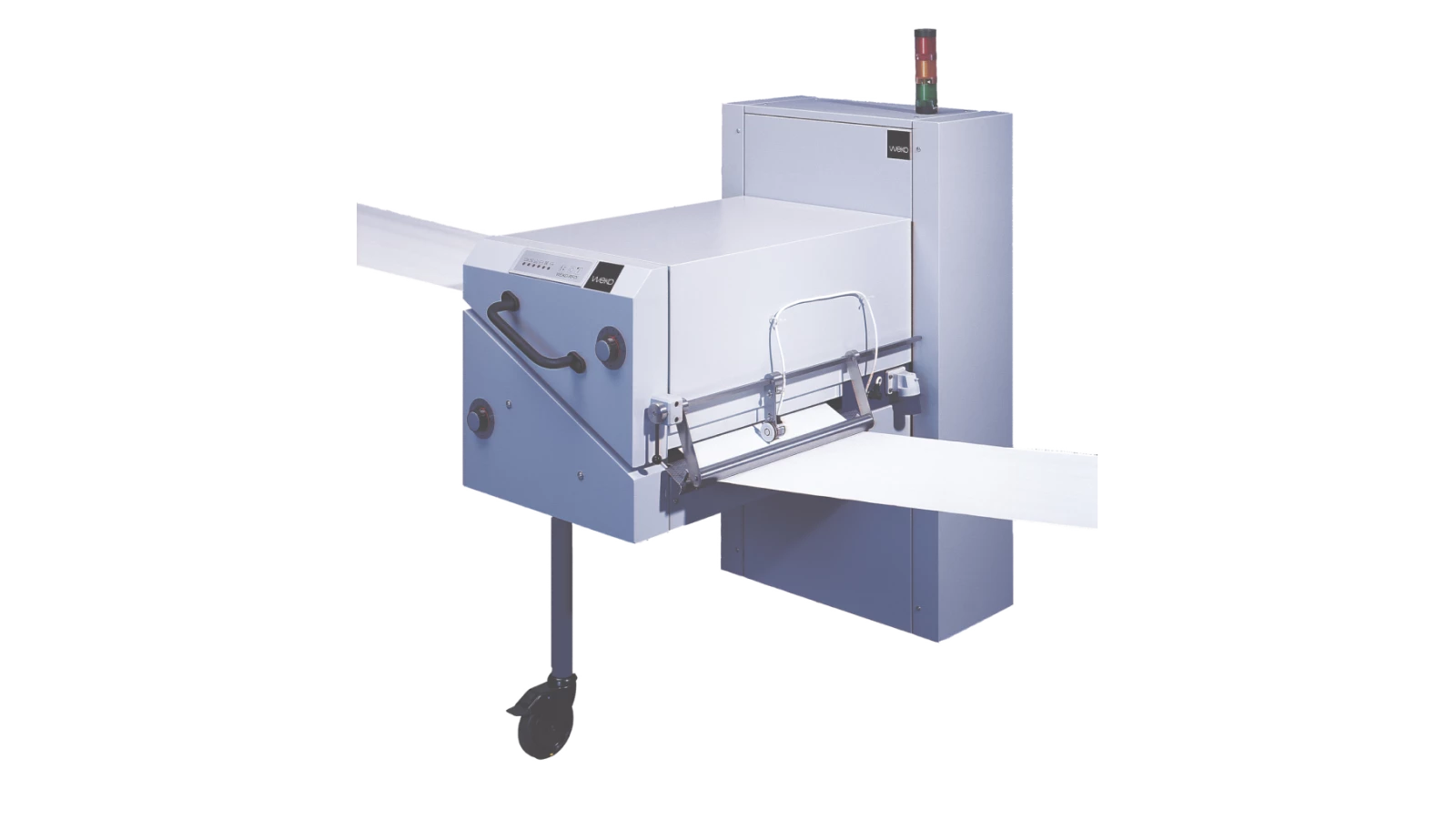

Other converting products

Find the solution that is right for you.

.png)