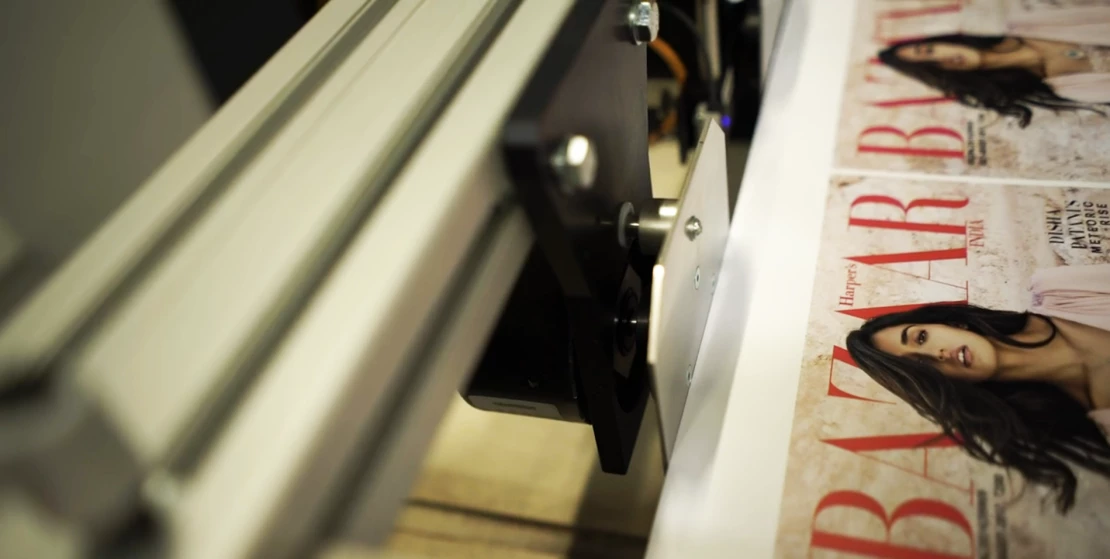

Can you print books more sustainably?

The global demand for paper keeps rising every year, making recycled paper and the use of FCS-certified paper a current standard in the printing industry. But it’s not just a practical necessity that forces the industry to print sustainably, today’s consumers also expect eco-friendly book production. So, how do we meet those demands and what options are there for greener book printing?

Need advice from our experts?

Meet today’s standards of sustainability, find a smart solution to paper supply issues and produce high-quality results with digital printing.

Want to know more about the connection between inks, recycling and deinkability of paper?

High-scoring deinking

Xeikon’s dry toners score high on the International Association of the Deinking Industry’s scale of efficient deinking, with a score of 90 out of 100!

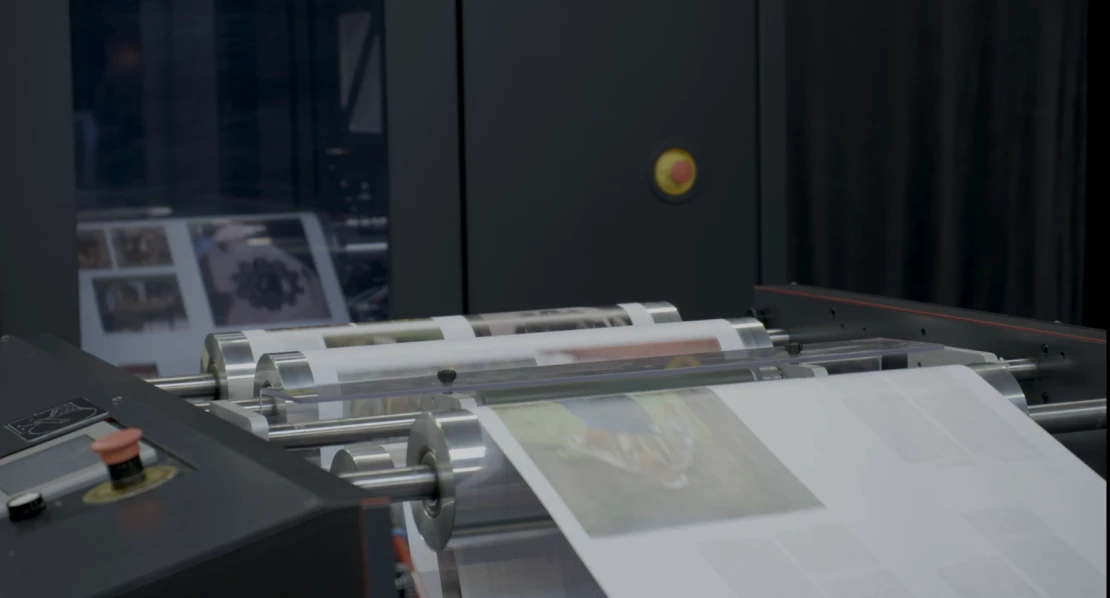

Sparing with water

Xeikon print tech is a dry process, where water is only used to cool the printheads in a closed circuit in the machine.

Ethical and harm-free materials

We carefully select the raw materials of our toners, making sure they’re sourced ethically and don’t include harmful substances.

Print on demand

With digital book printing, you can produce books tailored to your customer’s needs. That means no surplus stock and less printing waste.

Substrate flexibility

Dry toner technology allows you to use any substrate you have in stock. You’re no longer dependent on a certain paper mill or brand.

Green energy-centric

The Xeikon toner and press assembly plant runs on 100 % green energy.