13/01/2017

by Danny Mertens

Short-run print quality

Admittedly, in the early days of digital printing, consistent quality was an issue. The limitations of the technology meant that what was won in printing speed and setup cost was actually lost in maintaining quality. That’s the reason why digital label production took a while to enter the mainstream since its introduction in 1993.

Digital presses have caught up with conventional technology

Fortunately, those days are long gone. Today, we are happy to say that digital presses have caught up with conventional technology in terms of quality standards. As a matter of fact, today’s digital presses can produce higher quality images than flexo – comparable to offset or gravure printing. The overall quality of the Xeikon 3300, for example, with its 1200 dpi resolution and automatic quality control, is so close to conventional machines that most customers don’t even notice the difference. In some markets, such as food and cosmetics, digital output is actually preferable because of the non-toxicity of the dry toner.

The success of digital presses also pushed flexo technology forward. For example, the new generation narrow web flexo presses come with reduced setup times. In other words, conventional presses have not lost their appeal. In fact, for most long-run jobs they are still the preferred choice. The way we see it, digital perfectly complements conventional technology.

1200 dpi quality

Image quality is a complex issue, determined by a combination of hardware, software, consumables and processes. As a result, Xeikon dry toner electrophotography and true 1200 dpi (a dot size of 21 μm) combined with 4-bit variable dot density offer smooth solids and blends with rich color depth and subtle contrasts, ideal to reproduce the most vibrant images. Our presses are equipped with several automated quality control features, ensuring uniform and accurate colors and color consistency, not only across a label and from label to label, but also between jobs and across presses.

Furthermore, digital label printers have all these tricks up their sleeves to further improve the print quality, such as adapting the screen ruling to 130 or 150 lpi per element in the design, which can be automatically integrated into the workflow with Xeikon.

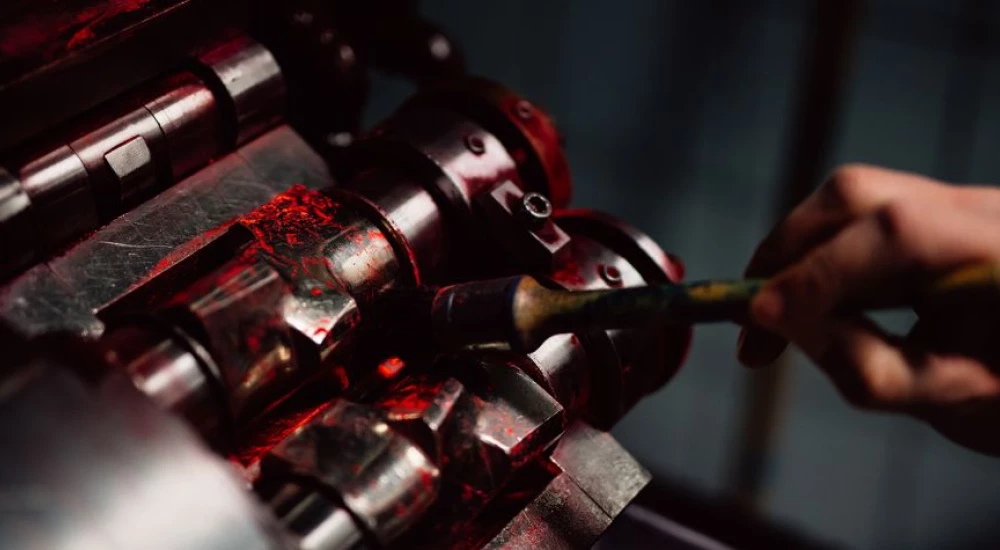

QA-I, ICE and Cheetah toner

Another decisive factor for the overall print quality is dry toner. Over the years, Xeikon’s market-driven research has ensured that our toner has been continually improved and fine-tuned to meet the requirements of our customers’ applications. For example, QA-I, the first dedicated label and packaging digital toner/ink, has been developed to meet the needs of the label and packaging industry, which places high demands on food safety and lightfastness, and it is used with the Xeikon 3000 Series.

ICE toner was launched in 2013 to broaden the application range for the label and packaging market. Based on QA technology, this toner uses a different core resin enabling the fusing at significantly lower temperatures making it highly suitable for printing on heat-sensitive substrates, such as PE and direct thermal paper labels.

Xeikon’s latest innovation is the Cheetah toner developed to run on the Xeikon CX3. Launched in 2015 and printing at a top speed of 30 m/min (98ft/min), the Xeikon CX3 is the fastest and most productive digital five-color narrow-web label press on the market in the top-quality range. To ensure superior print quality even at these high speeds, the charging characteristics of the and transfer geometry of the toner was modified.

Quality and lightfastness

Lightfastness is a measure of how well a printed image resists discoloration or fading as a result of exposure to overall present UV light over time. Products sitting on a store shelf or in a warehouse are often exposed to direct sunlight for hours on end. The UV light affects the color pigments, causing the image to lose its brightness over time.

Here too, Xeikon’s digital technology shines. From the start, Xeikon invested in high quality toners with great lightfastness scores without any additional protective finishing. The goal was to achieve this for both CMYK and spot colors (with the exception of spot color blue which is generally known to be very sensitive to UV light). Several independent tests have shown that all current Xeikon process colors meet or exceed rating 6 on the Blue Wool Scale. In other words, with Xeikon toner your prints will remain their vibrant selves for a very long time.