10/10/2023

by Jeroen Van Bauwel

By Jeroen Van Bauwel (Director Solution Design at Xeikon) and Eduard Vidra (Business Manager at Litograf)

---

Litograf has an impressive track record with its Xeikon presses and the hybrid approach it’s taken to digital printing. Its multi-layer collagen labels offer a multi-finish and have proven popular on socials thanks to successful partnerships with social media influencers on Instagram. When Eduard Vidra presented at our most recent Panther days, he mentioned something that really caught my attention - that Litograf would often have to go back to designers to make sure their designs were properly created and optimized for label printing. This got me thinking, “What should designers know before designing something for digital print?” I asked Eduard to share some top tips for creatives when working in this space, so we can all save ourselves some back-and-forth time.

1. Talk to your producer first

The process of creating a product label should always start with a conversation with the label producer themselves. That initial brief, and any clarifications that follow, are vitally important in establishing the key goals for any design. Some designers can go ‘off brief’, which can be an expensive outlay if multiple revisions are required, but the bigger issue is ensuring the visuals that are in development are suitable for the print setup and any selected materials. Matching dreams and expectations to execution realities is essential before kicking off any design project.

What do you need to discuss with your printer?

A. Budget, cost, and value

We’re not just talking about the design budget and print costs here, but the overall monetary value that this product represents. Is it a premium product with a high margin or something more economical? The complexity of a label design and the print embellishments will have a profound impact on its overall cost, so planning ahead ensures you’re not stung further down the line. But if you align all elements beforehand, you’ll end up with a label that lives up to every expectation and complies with all monetary realities.

B. What toolkit is there to work with?

There are plenty of tools out there to help enrich the design and functionality of a label without adversely affecting the cost. Many of these are already a part of the digital print process, such as adding variable elements (numbering, barcodes, etc), deeper design elements (such as VariOne functionality), special colors (such as spot colors), or introducing security features, track & trace and much more. Asking your printer beforehand what they print on, and which digital print features are available will help any visual professional to get the creative flow going. Looks expensive on the shelf, but isn’t on the press.

C. Are we prioritizing form or function or going for both?

When a label or piece of packing arrives in the store, it has one simple objective: grab the customer’s attention. This is the brand owner’s last opportunity to convince the customer this product is worth buying, so we want them to see a design that compels them to pick it up to learn more. This greatly increases the chance of said customer making a purchase.

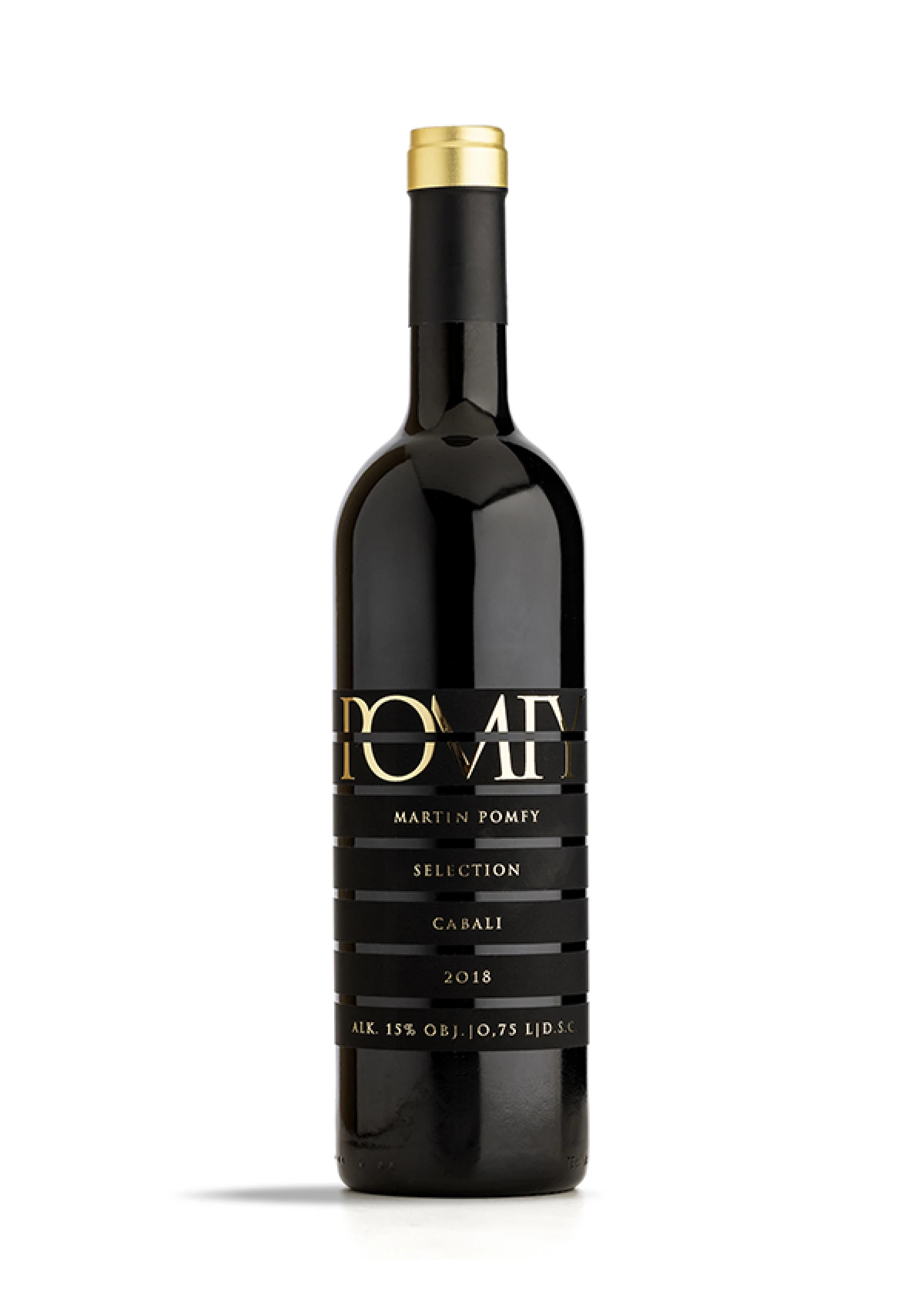

Here’s an example of how a designer can use an effective design that eschews extra embellishments and creates a simple yet eye-catching design. The birds on this wine label - and the bubble, which contains some interesting little facts - were printed at a photo-like quality using a Xeikon CX300 toner press. This example shows just how much vibrancy and detail can be achieved when a designer produces something with digital printing in mind.